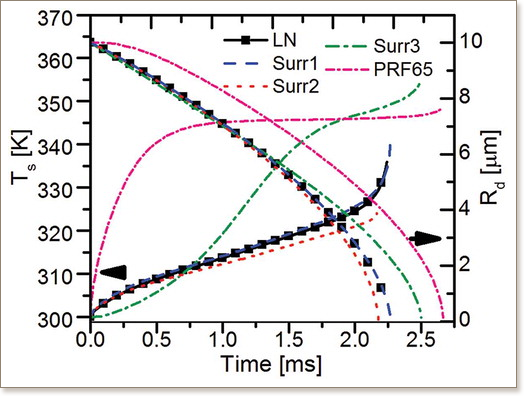

Light naphtha (LN) is gaining interest in internal combustion (IC) engine applications due to its low refining cost and higher heating values compared to commercial gasoline. To properly describe the chemical and physical behavior of the LN fuel under IC engine conditions, a systematic procedure to develop unified physical and chemical surrogates is described. The reduced component models to describe the chemical characteristics of LN are combined with the effective thermal conductivity/effective diffusivity (ETC/ED) model to represent the accurate evaporation behavior. Three surrogate fuels consisting of three to five components are presented and their performance in heating and evaporation of a single LN droplet is compared against the conventional primary reference fuel (PRF65) surrogate which is based on chemical aspects only. Unlike the previous approaches, the new surrogates also target matching the hydrogen-to-carbon ratio and research octane number in order to accurately describe the chemical behavior of the fuel. Subsequently, the performance of the surrogates in describing spray characteristics is tested by computational simulations compared with experimental measurements. The simulations were carried out using CONVERGE CFD package. The ETC/ED model was implemented into CONVERGE using user-defined functions. The predicted spray penetration length for the developed surrogates shows good agreement with the experimental data. At engine-like conditions, the ETC/ED model predicts higher vapor mass than the infinite thermal conductivity/infinite diffusivity model, hence showing the expected trend by incorporating the realistic droplet heating process.