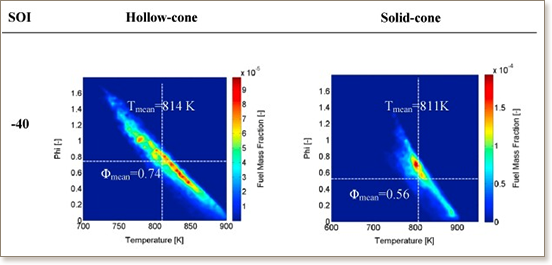

Injectors play an important role in direct injection (DI) gasoline compression ignition (GCI) engines by affecting the in-cylinder mixture formation and stratification, which in turn impacts combustion and emissions. In this work, the effects of two different injector geometries, a 7-hole solid-cone injector and an outwardly opening hollow-cone injector, on fuel mixture stratification in a GCI engine were investigated by computational simulations. Three fuels with similar autoignition kinetics, but with different physical properties, were studied to isolate the effect of the combustion chemistry on combustion phasing. In addition, start of injection (SOI) sweeps relevant to low-load engine operating conditions were performed. The results show that physical properties of the fuel do not have significant influence when using a hollow-cone injector. Richer mixtures were observed at all the studied SOI (−40 to −14 CAD aTDC) cases, which can be attributed to the nature of the hollow cone spray. At later SOIs (−18 and −14 CAD aTDC), the richer mixtures are accompanied by lower mean in-cylinder temperature due to the charge cooling effect, which surpasses the equivalence ratio effect. The effect of fuel physical properties on combustion phasing was evident in multi-hole injection cases, which can be attributed to the differences in mixture stratification and equivalence ratio distribution at the time of ignition.