The role of fuel spray in the combustion process is to break up the liquid fuel into smaller droplets thus increasing the surface area for evaporation to provide gaseous fuel for combustion. Ultimately the fuel spray quality and its distribution and mixing in the combustion chamber determine the quality of the combustion process. The fuel injection and spray break-up process are very complex which involves turbulent and time-dependent two-phase flow. Consequently modeling the spray phenomena have been very challenging, particularly in the region near the nozzle exit. A realistic spray break-up model should capture the necessary two-phase flow phenomenon occurring both in the internal nozzle flow and outside the injector nozzle.

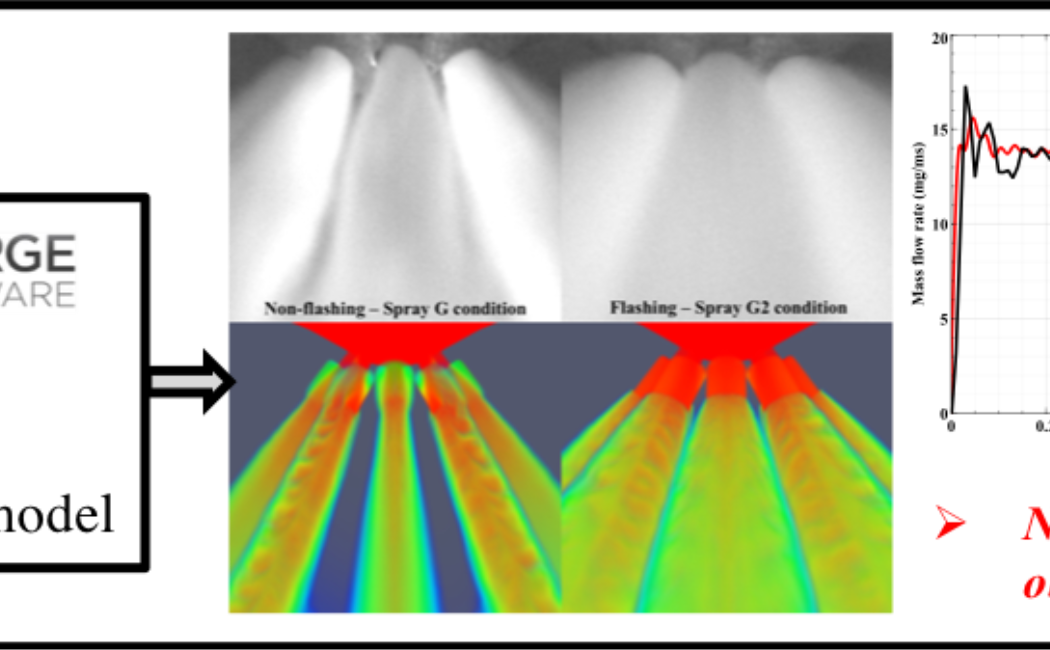

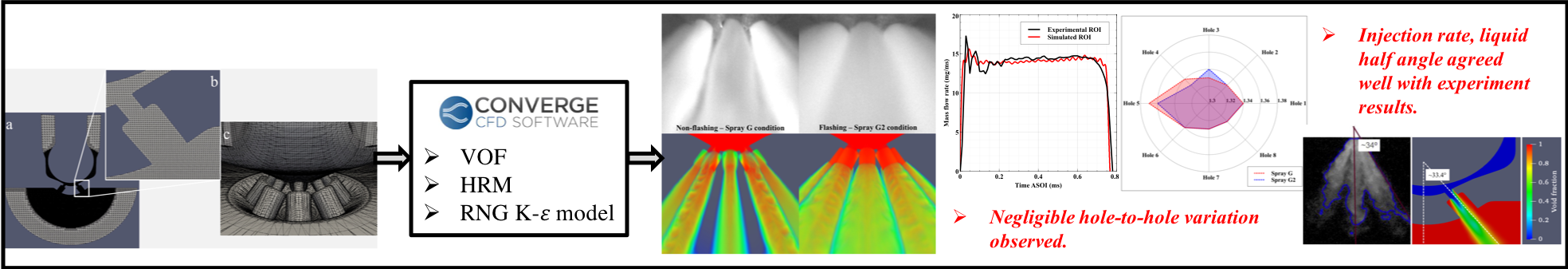

Fuel injection always involves phase-change phenomena. The two most common phase-change phenomena are cavitation and flash boiling. The phase-change process is highly complex. Cavitation takes place in high-pressure diesel injectors and is pressure-driven vaporization taking place at low temperatures. At high fuel temperatures, more energy is required for phase-transition per unit volume of vapor due to high saturation vapor density compared to that of low-temperature fuel. Thus, flash boiling is a thermal non-equilibrium process, unlike cavitation. At KAUST, we can accurately model the in and near nozzle two-phase flow phenomenon.

New spray models and chemical reaction mechanisms developed are tested against the experimental spray characteristics obtained from KAUST Spray Lab. Vaporizing spray characteristics such as liquid length, vapor penetration, droplet Sauter mean diameter (SMD), droplet size distribution and spray combustion characteristics such as ignition delay and flame lift-off length are modeled using RANS and LES computations.

In and near nozzle two-phase flow simulations